Laser cutting

We are there for you - technology and know-how

Separation process

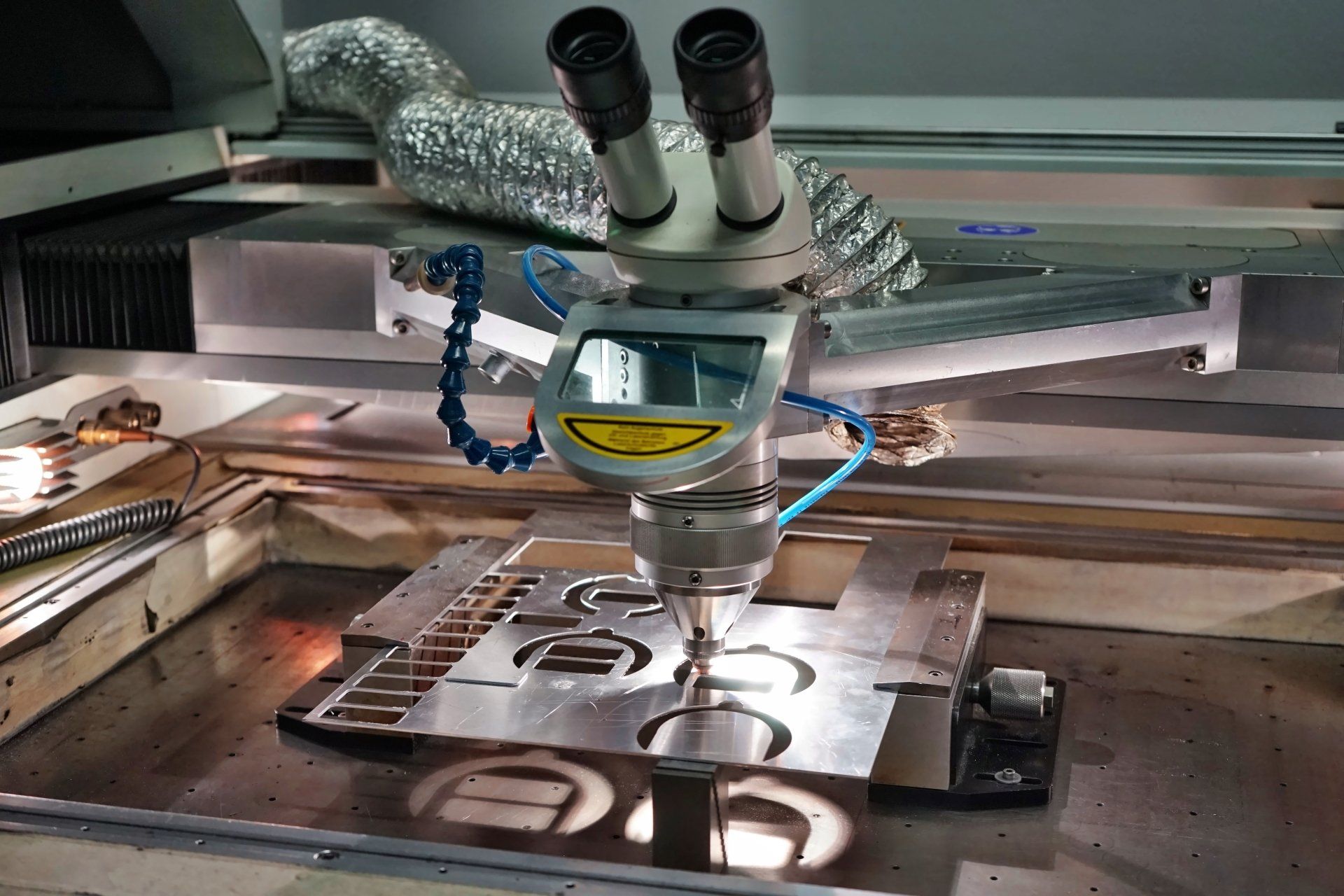

Laser cutting is a thermal cutting process for plate-shaped materials and 3-dimensional bodies using a laser.

The process is used when complex outlines, precision, high speed processing, 3D opening production and contact-free or almost contact-free processing is required. Areas of application are: precision engineering, electronics production, medical technology, vehicle and mechanical engineering, jewellery production as well as prototypes and small series production.

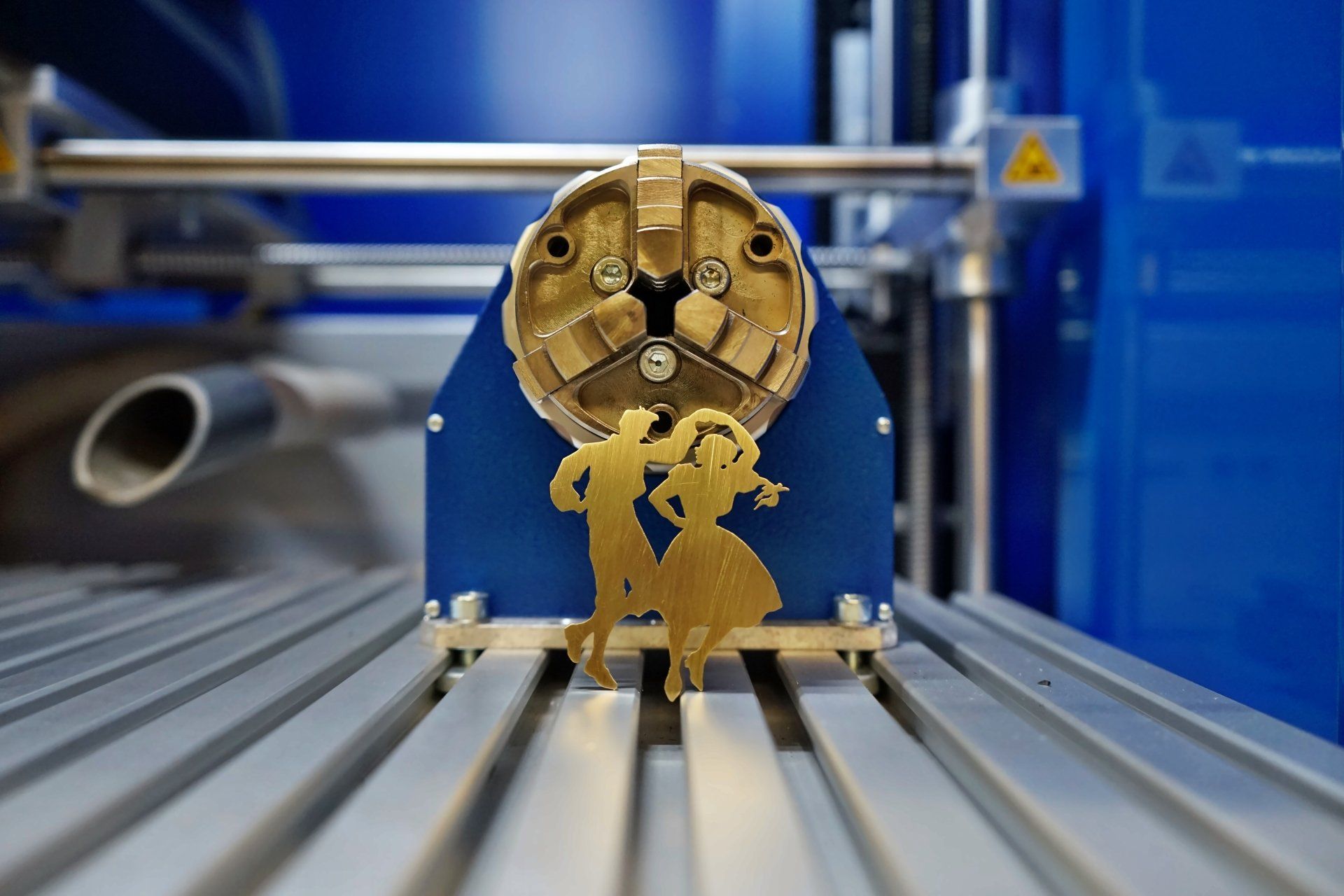

Laser cutting and welding machine AW 300

With our compact AW 300 laser system, we cut, automatically and precisely, sheet metal with a thickness of up to 2 mm. Draw - transform - cut. The cutting paths generated by CAD are converted in a matter of minutes and can be cut directly.

Laser cutting area (X, Y, Z): 500 x 450 x 350 mm

Laser cuts in the range: from 0.1 to 2.0 mm

Materials that can be cut: aluminium, stainless steel, steel, brass, copper, silver, gold, titanium,

Possible applications: housing parts, pipes, rings, sheets

Data provision: Format .dxf

Laser cutting - the advantages:

Laser cutting - the industry sectors:

Inquiries and information to:

info@jutz-lasertechnik.at

We are happy to help!