APPLICATIONS FOR ALPHA LASER

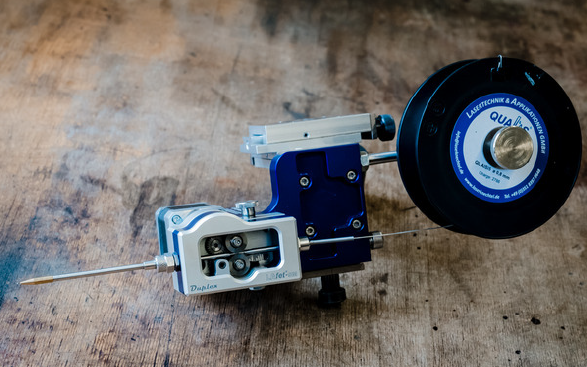

Programmable laser wire feed system LAfet®

Laser welding wires from ø 0.25 to ø 0.5 mm are fed with high precision with LAfet. The control logic allows precise adaptation to the laser welding process. The fixation of LAfet® on the laser head takes place via the rail guide *, resonator clamp * or individual attachment (* valid for Alpha Laser AL). Variable speeds allow precisely timed wire movements at the beginning, during and at the end of each weld. Process reliability and maximum reproducibility of the laser welding with optimized welding time are distinctive properties that speak for the use of LAfet®.

Downloads (PDF)

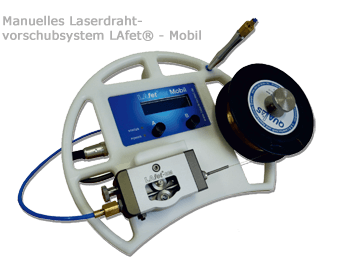

Manual laser wire feed system LAfet® - Mobil

The laser wire filler material is fed into the melt continuously and with the highest precision via the handle, under direct observation of the laser welder. The beginning and end of the "laser wire feed" are implemented by contacting or removing the laser wire tip from the welding component. This function can optionally be carried out using the foot switch. The adjustment / positioning of the free wire end (wire protrusion) on the capillary nozzle is done by a motor using the corresponding function of the control box. After inserting a new laser wire reel, the free end of the wire is passed manually through the drive unit and then transported by motor through the "duplex capillary tube" and the handle to the nozzle tip.

Downloads (PDF)

Brochure as PDF: LAfet®-SM mobile laser wire feed system

VDM 330

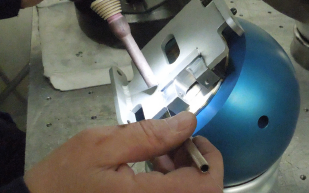

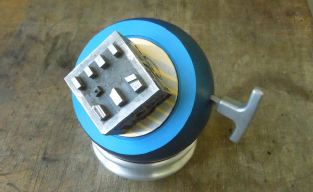

Large components with a rotationally symmetrical laser welding contour are precisely positioned and rotated with the VDM 330. The turntable is compact and only takes up a height of 79 mm. The connection is made to the ALPHA laser devices *: ALW, ALT, ALFlak and ALFlakMax. The minimum web speed in Ø 320 mm is approx. 0.7 mm / s.

Downloads (PDF)

Brochure as PDF: Vertical rotary axis module VDM 330

Rollenbock RoBo-1

Rotationally symmetrical, long components that are rotated with the ALPHA LASER rotary axis D125 can be safely stored and precisely welded.

Downloads (PDF)

Inquiries and information to:

info@jutz-lasertechnik.at

We are happy to help!