Laser Engraving and Labelling

We are there for you - technology and know-how

Operation area

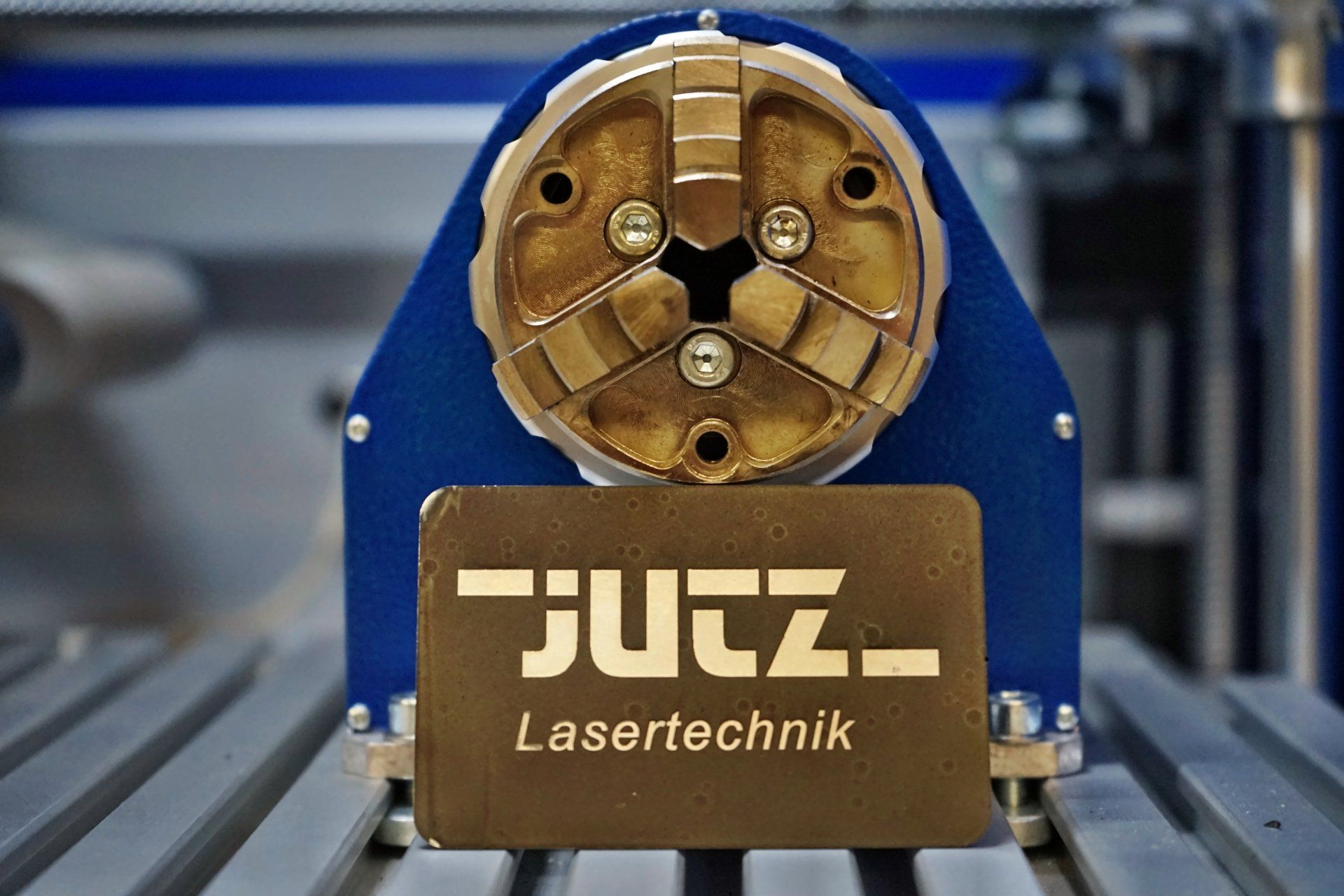

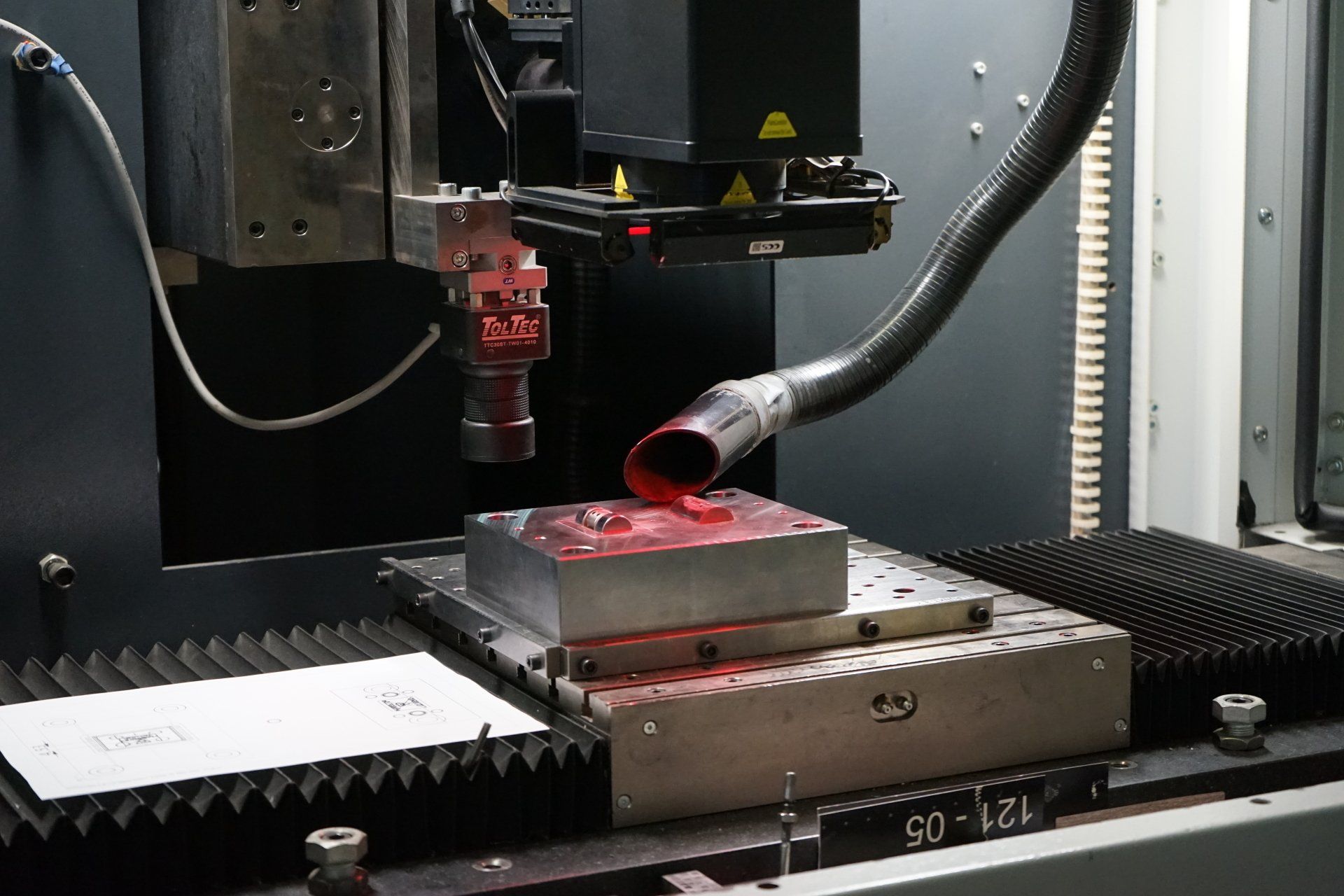

Laser engraving offers you the opportunity to support and replace conventional processes such as die sinking or milling. Thanks to a rotary swivel unit on the machine, we can also process round parts, 3D free-form surfaces and cover lettering. It is also possible to remove paint from coated, lacquered and anodized surfaces.

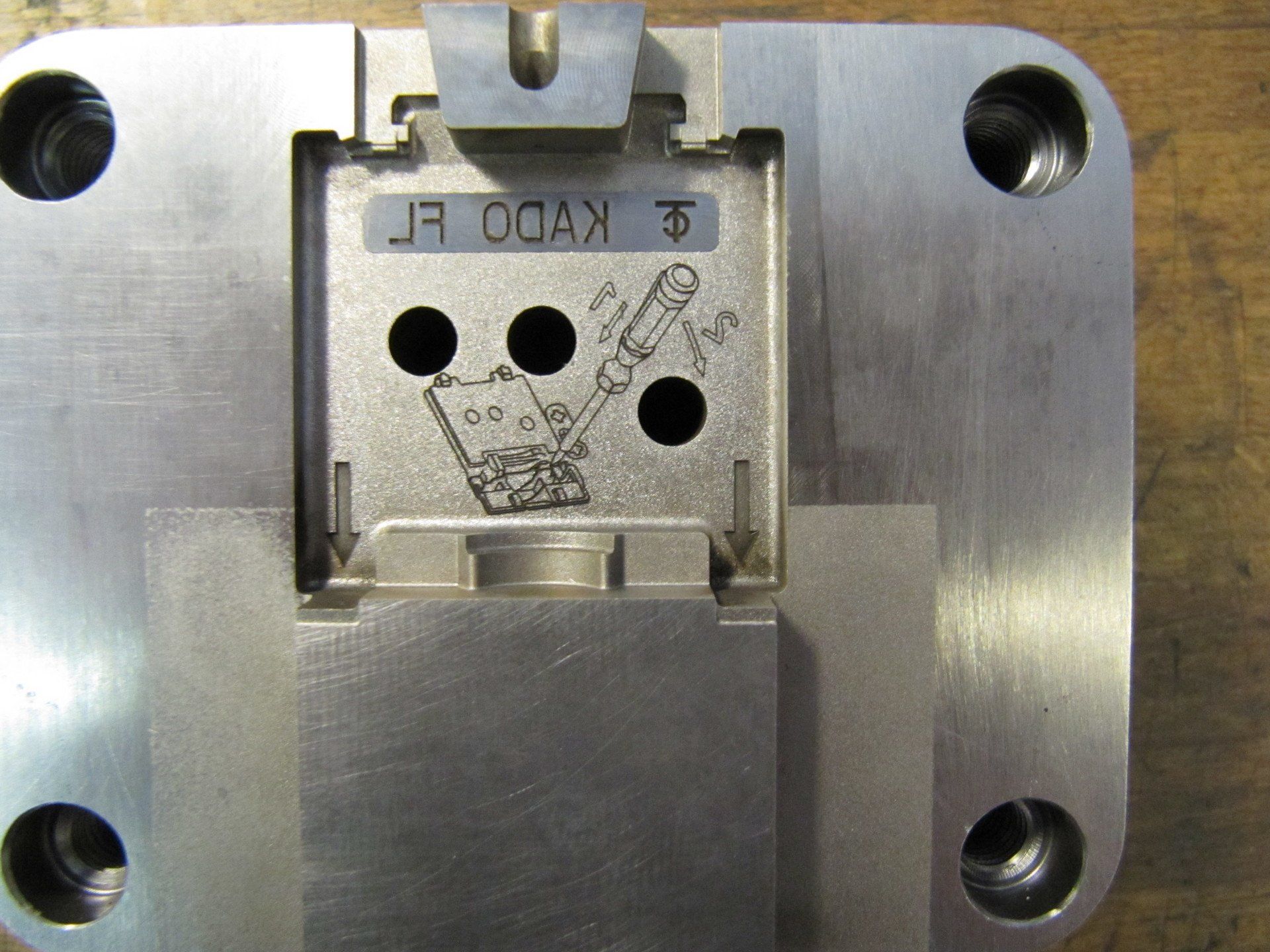

The laser engraving process offers you many advantages such as: Repeatability or precise removal on many materials. Since the workpieces do not have to be fixed, it is also possible to process small, filigree components such as clocks or embossing stamps. Within injection molding tools, many cavities can be deeply-engraved with repeat accuracy and in a minimal time frame.

This makes the laser the ideal tool compared to elaborately manufactured CU electrodes. Data for the each engraving is saved with ease and can be used again and again without wear and with the same high quality.

With our system, engraving within the layering process is also possible on inclined surfaces or curves (3D free-form surface).

Countless data sets for fonts enable us to carry out many personalised engravings or labels.

Economic Advantage

The production of complex electrodes can be done away with and the reproducibility of engravings directly in the mold insert becomes standard thanks to the contactless process. In addition to this, due to the archiving of data, no storage of electrodes is necessary.

The data sets can be used again and again and their size can be adjusted at any time by scaling them. Engravings in 3D free-form surfaces can be lasered directly by layering STL data in mold inserts.

Materials that can be engraved and written on are:

Application examples for 2D and 3D engraving:

Send us your task or make an appointment with us in-house and we will find the optimal solution.

Please send inquiries to the following email address:

info@jutz-lasertechnik.at